Top 7 Benefits of Epoxy Floor Covering for Concrete Surfaces

Jonathan Welter, Flooring & Concrete Preparation Specialist at Midwest Floor Shield

Jonathan Welter is a flooring and concrete preparation expert with over 15 years of experience designing, installing, and maintaining high-performance epoxy and polyaspartic floor systems for residential and commercial properties. At Midwest Floor Shield, serving areas like Roscoe, Illinois, and Madison, Wisconsin, he oversees projects that combine moisture testing, crack repair, surface profiling, and system selection to ensure durable, safe, and attractive floor coatings.

Jonathan’s hands-on expertise allows him to explain technical flooring solutions in practical terms, helping homeowners prevent premature coating failures, reduce maintenance costs, and maximize their flooring investment. He is passionate about educating property owners on proper subfloor preparation, moisture mitigation, and coating choices to ensure long-lasting results.

Epoxy floor coverings have grown in popularity as a versatile flooring solution for residential spaces, thanks to their remarkable durability and aesthetic appeal. One of the key benefits of epoxy flooring is its exceptional resistance to wear and tear. Unlike traditional flooring materials, epoxy creates a seamless barrier that can withstand heavy foot traffic, spills, and even chemical stains. This makes it an ideal choice for high-traffic areas like kitchens, basements, and garages. In addition to their durability, epoxy floors are also known for their safety features. The non-slip surface can significantly reduce the risk of slips and falls, making them a practical choice for homes with children or elderly occupants.

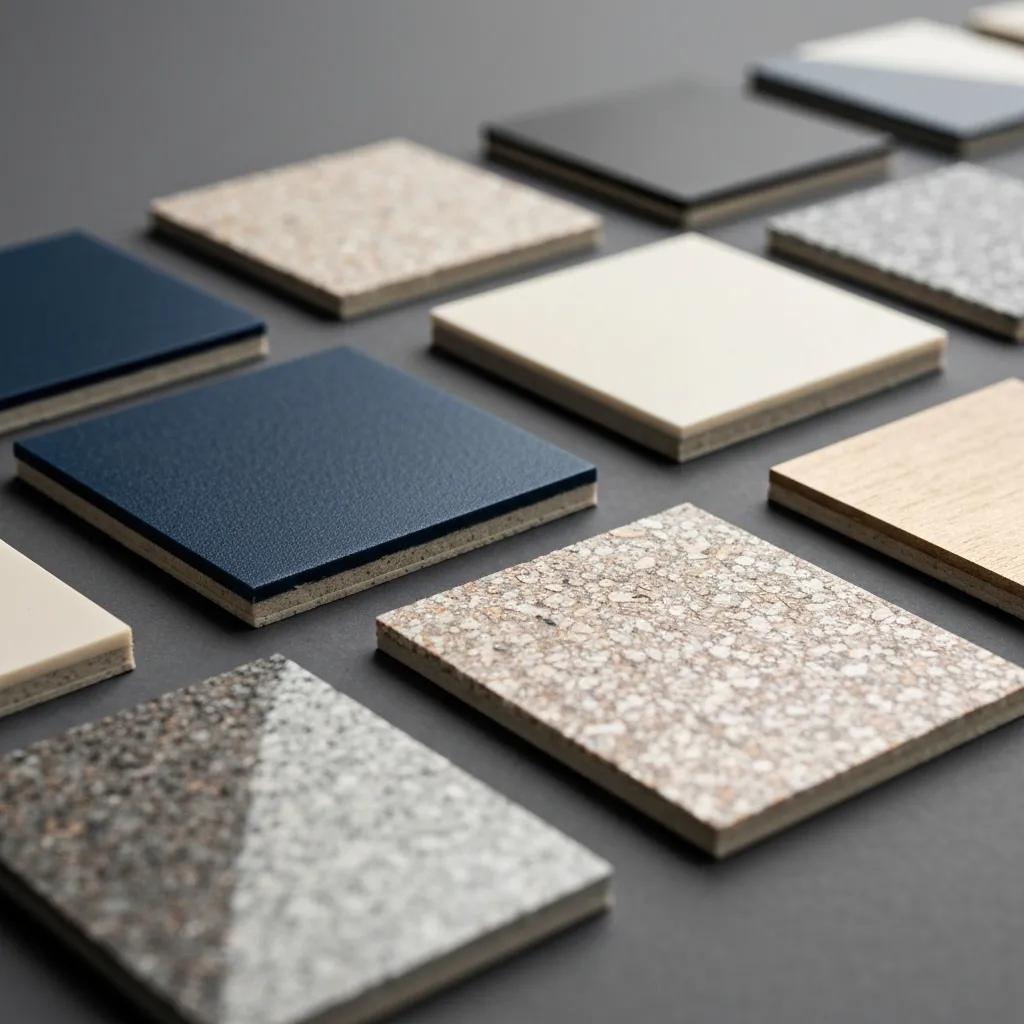

Beyond their functional attributes, epoxy floors offer a wide range of design possibilities that can elevate the overall look of your home. Available in various colors and finishes, epoxy flooring can be customized to suit any aesthetic, from sleek and modern to warm and rustic. Homeowners can choose from a glossy or matte finish, or even incorporate decorative elements like metallic pigments or colored flakes for added visual interest. This flexibility not only enhances the beauty of your spaces but also reflects your personal style. Additionally, epoxy floors are easy to clean and maintain, requiring only minimal effort to keep them looking pristine. With these benefits combined, choosing epoxy floor coverings can lead to a durable, safe, and stunning flooring option that adds value to your home without compromising on functionality.

Epoxy floor coverings are a two-part resin system that chemically bonds to concrete, creating a seamless, high-strength surface ideal for garages and basements. This article explains seven advantages homeowners often overlook — from moisture control and chemical resistance to improved hygiene, safety, and long-term cost-effectiveness — and shows how epoxy works on a technical level while remaining practical for everyday home use. If you’re worried about oil stains, basement dampness, or cracked concrete, this guide outlines how epoxy addresses those problems and when additional repairs or waterproofing are needed. Below are seven core benefits to frame the rest of the article, followed by clear guidance on maintenance, aesthetic options, safety additives, and cost comparisons. After the benefits list you’ll find a helpful next step: homeowners concerned about moisture or concrete damage can schedule a free inspection for waterproofing and repair assessment to confirm subfloor readiness and scope of work.

Seven lesser-known benefits of epoxy floor coverings include:

Epoxy creates a seamless, non-porous membrane that resists moisture and vapor intrusion.

Epoxy resists common garage chemicals and simplifies cleanup of oil and solvents.

Epoxy dramatically increases abrasion and impact resistance for heavy vehicle or workshop use.

Epoxy minimizes dust and allergens versus bare concrete or carpeted surfaces.

Decorative epoxy options improve light reflectivity and perceived space in basements and garages.

Proper epoxy systems provide long service life, lowering lifecycle cost vs. frequent repairs.

Slip-resistant additives and texture choices enhance safety in wet or oily conditions.

These benefits set the stage for detailed sections that follow about durability, chemical resistance, maintenance, aesthetics, cost-effectiveness, safety, moisture control, and complementary services. Each section explains the mechanism, practical examples, and steps homeowners can take next.

What Makes Epoxy Flooring the Most Durable Floor Coating for Concrete Surfaces?

Epoxy flooring becomes the most durable coating for concrete by chemically bonding a resin-hardener matrix to the substrate, which transfers loads across a continuous surface and resists impact and abrasion. This bonding mechanism prevents delamination and creates a tensile, wear-resistant layer that performs well under vehicle weight, tool drops, and frequent foot traffic. Because the system is seamless, it reduces localized stress points that lead to spalling or chipping on untreated concrete. Understanding these durability mechanisms helps homeowners choose the correct epoxy system for their garage or basement use, and it leads naturally to how epoxy protects common concrete problems.

How Does Epoxy Flooring Protect Garage and Basement Concrete?

Epoxy protects garage and basement concrete by sealing surface pores, filling minor imperfections, and forming a wear layer that prevents oil, solvents, and particulate abrasion from weakening the substrate. In practice, epoxy reduces stain penetration, limits freeze-thaw spalling by keeping moisture out of surface voids, and minimizes dusting that accelerates surface degradation. For example, a workshop with power tools benefits because metal shavings and grit are contained and removed easily rather than grinding into the concrete. Proper surface profiling before installation ensures the epoxy bonds into the concrete matrix, which is why preparation is critical to translate protective chemistry into long-term performance.

Why Is Epoxy Flooring a Long-Term Investment for Homeowners?

Epoxy is a long-term investment because its combined resistance to wear, chemicals, and moisture extends concrete service life and reduces the frequency of repairs or replacement, effectively lowering annualized flooring cost. Typical residential epoxy systems, when installed with proper prep and maintenance, commonly perform for a decade or more before major recoating, making the amortized yearly cost competitive with alternatives that require more frequent upkeep. Beyond direct cost savings, epoxy improves usable space — turning a dingy garage or basement into a clean, functional area that supports hobbies, storage, or a workshop. That practical return, combined with lower maintenance demands, frames the economic rationale homeowners use when comparing flooring options.

How Does Epoxy Flooring Provide Superior Chemical and Stain Resistance?

Epoxy achieves superior chemical and stain resistance by creating a continuous, non-porous polymer layer over concrete that prevents liquids from penetrating and reacting with the substrate. The cured surface is chemically inert to many household and automotive fluids, which means spills bead up and remain on the surface for prompt cleanup. This mechanism reduces staining, prevents long-term hydrocarbon penetration, and makes routine maintenance straightforward. The practical outcome is less time spent scrubbing and a lower chance of permanent damage to the concrete beneath, which naturally leads to a list of common substances epoxy handles and recommended spill responses.

The following table summarizes common garage and basement chemicals, expected resistance, and recommended cleanup steps to keep the surface protected.

Substance

Resistance Level

Cleanup Recommendation

Motor oil

High — beads and wipes away

Wipe up promptly with absorbent, then mop with mild degreaser

Gasoline

Moderate — quick action needed

Contain vapors, absorb liquids, ventilate area, neutralize residue

Antifreeze (ethylene glycol)

High — low staining when cleaned

Blot immediate spill; mop with pH-neutral cleaner afterward

Brake fluid

Moderate — may soften some coatings over long exposure

Wipe immediately and rinse; inspect topcoat if prolonged exposure occurred

Household cleaners/solvents

Variable — many are resisted

Use manufacturer-recommended cleaners; avoid strong solvents for topcoat longevity

This comparison shows epoxy’s practical advantage for everyday garage spills, while also noting that fast cleanup preserves the coating and prevents edge damage over time.

What Common Garage and Basement Chemicals Does Epoxy Resist?

Epoxy resists a broad range of substances encountered in residential garages and basements, including motor oil, many antifreezes, household cleaning fluids, and diluted solvents, because its cured surface is non-absorbent and chemically stable. That said, some aggressive solvents and prolonged chemical exposure can soften or dull specific topcoats, so immediate containment and cleanup remain important. Battery acid and highly concentrated industrial chemicals represent special cases where protective measures or different system choices are required. Knowing which chemicals pose limits informs maintenance procedures and selection of a tougher chemical-resistant epoxy system if the space will see heavy exposure.

How Does Epoxy’s Non-Porous Surface Make Cleaning Easier?

Epoxy’s seamless, non-porous finish prevents dirt and grime from embedding in microscopic pores, so routine cleaning becomes a simple sequence of sweeping and mopping rather than intensive scrubbing. Homeowners typically follow a weekly sweep or dust-mop and a monthly pH-neutral mop to maintain appearance; spot-treat stubborn marks with a mild degreaser and a soft brush. Because contaminants remain on the surface, sanitizing is more effective and faster than on bare concrete or textured tiles. These cleaning efficiencies reduce long-term upkeep costs and support improved indoor hygiene, which connects directly to the next section about maintenance and allergens.

Why Is Epoxy Flooring the Best Choice for Effortless Maintenance and Improved Hygiene?

Epoxy supports effortless maintenance and improved hygiene by eliminating pores and seams where dust, pollen, and allergens normally accumulate, enabling efficient cleaning and sanitation routines. The smooth finish reduces the reservoir of particulates compared with rough concrete or textile flooring, lowering visible dust and the effort required to keep floors tidy. For homes with pets or occupants sensitive to allergens, this reduced entrapment simplifies cleaning workflows and contributes to perceived indoor air quality improvements. Practical maintenance patterns and cleaning product recommendations follow, helping homeowners maintain both aesthetics and hygiene over time.

A simple cleaning routine keeps epoxy floors performing well and looking new.

Daily/Weekly: Sweep or dust-mop to remove loose debris and prevent abrasive wear.

Weekly/Monthly: Mop with a pH-neutral cleaner diluted in warm water and rinse well.

Spot Treatment: Apply a mild degreaser for oil spots, use a soft-bristle brush, then rinse thoroughly.

What Simple Cleaning Routines Keep Epoxy Floors Looking New?

A practical schedule for epoxy care begins with daily or weekly dust removal to stop abrasive particles from dulling the finish and progresses to routine mopping with a pH-neutral cleaner for general soil removal. For heavier soils or oil stains, use an absorbent to lift the spill, follow with a mild degreaser, and finish by rinsing with clean water to avoid chemical residue. Avoid harsh solvents or abrasive pads that can abrade the topcoat and weaken chemical resistance over time. Following this straightforward regimen preserves both hygiene and the coating’s functional properties, which naturally reduces allergen reservoirs as described next.

How Does Epoxy Flooring Reduce Allergens and Dust in Your Home?

Epoxy reduces allergens and dust by creating a sealed surface that prevents particulate trapping and simplifies removal through routine sweeping and mopping. Without fibrous or porous substrates, pollen, pet dander, and dust mites have fewer places to collect, which means cleaning removes a higher percentage of airborne allergen reservoirs. For spaces prone to dampness, epoxy also helps by preventing moisture accumulation in surface pores that can support mold on floors, but moisture sources behind the slab still require inspection. Improving floor hygiene through epoxy complements broader moisture-control measures to protect indoor air quality and occupant comfort.

How Can Epoxy Flooring Enhance Your Home’s Aesthetic Appeal and Customization Options?

Epoxy flooring offers wide customization—solid colors, decorative flakes, and metallic finishes provide distinct visual effects that suit garages, basements, and transitional living spaces while improving light reflectivity and perceived room size. These design choices let homeowners match interior palettes, hide minor surface imperfections, or create a high-end glossy floor that elevates a workshop or hobby space. Because visual impact contributes to how spaces photograph for listings, aesthetic upgrades can influence desirability and perceived value. The next list outlines common residential finishes and their best-use scenarios to guide design selection.

Common residential epoxy design options fall into several practical categories:

Flake/Broadcast Systems: Provide texture and camouflage for garages and high-traffic basements.

Solid Color Coatings: Offer clean, uniform surfaces ideal for utility areas and workshop floors.

Metallic Epoxy Finishes: Create glossy, depth-rich appearances suited for finished basements or showroom-style garages.

Broadcast with Topcoat: Combines decorative appearance with a durable protective clear topcoat for longevity.

What Design Options Are Available for Residential Epoxy Floors?

Residential epoxy systems range from simple pigmented solids that provide uniform coverage to flake broadcast systems that hide imperfections and add grip, and metallic epoxies that produce a three-dimensional, polished look. Flake systems are commonly recommended for garages because they conceal stains and provide moderate texture, whereas metallic finishes suit finished basements or recreation spaces where a premium look is desired. Color choices and flake density influence reflectivity and slip characteristics, so specifying the right system ensures both beauty and function. Selecting a system also affects installation complexity and cost, which ties into the financial comparisons later.

How Does Epoxy Flooring Increase Property Value Through Visual Appeal?

Epoxy increases property value by improving the presentation and usability of secondary spaces like garages and basements, making them more attractive to buyers who see a clean, durable surface as an indicator of well-maintained home systems. A finished, glossy basement or a dry, clean garage can convert previously underused space into a functional workshop, storage area, or hobby room, enhancing the functional square footage buyers value. While aesthetic upgrades alone don’t guarantee higher appraisal figures, practical improvements that reduce visible wear and maintenance concerns strengthen marketability. Understanding these visual and functional benefits helps homeowners weigh the cost-benefit picture that follows.

Is Epoxy Flooring Cost-Effective Compared to Other Floor Coverings?

Epoxy is cost-effective when evaluated over a lifecycle because higher upfront installation costs are offset by reduced maintenance, longer service intervals, and extended concrete lifespan compared with options that require frequent repairs or replacements. Comparing typical upfront cost to expected years of service and annualized maintenance and replacement expenses clarifies the economic case for many homeowners. The following table compares epoxy to tile, paint, and concrete sealers across upfront cost, lifespan, and maintenance frequency to illustrate relative value and inform decisions about which system best fits a homeowner’s budget and use case.

Flooring Option

Typical Upfront Cost

Lifespan & Maintenance

Epoxy coating

Moderate–Higher upfront; lower lifecycle cost

8–15+ years with proper prep and maintenance; low annual maintenance

Tile (residential)

Moderate–High upfront

15–25 years but grout requires maintenance; susceptible to cracking

Concrete sealer/paint

Low upfront

1–5 years before reapplication; higher cumulative maintenance

Vinyl or modular flooring

Moderate upfront

10–20 years but may trap moisture at seams; replacement possible if damaged

This EAV-style comparison shows epoxy’s strength in balancing upfront investment with extended lifespan and lower recurring maintenance, making it competitive on an annualized cost basis for many residential uses.

How Do Initial Costs Compare to Long-Term Savings with Epoxy?

Initial epoxy costs depend on surface preparation, chosen system, and repair needs, but the key savings derive from fewer recoats, reduced repair cycles, and less time spent on cleaning and stain remediation. An amortized example shows that spreading the installation cost over 10 years often yields a comparable or lower annual cost than low-upfront alternatives that require more frequent replacement or heavy maintenance. Critical to realizing these savings is correct subfloor preparation; inadequate prep leads to premature failures and higher life-cycle cost, which is why inspection and repair interplay directly with economic outcomes.

What Energy Savings Result from Epoxy’s Light Reflectivity?

High-gloss epoxy finishes increase visible light distribution across garage and basement interiors by reflecting artificial and natural light, which can reduce perceived dimness and the need for additional fixtures. Improved lumen distribution can translate into fewer lighting hours or lower fixture counts to achieve comfortable visibility, especially in basements with limited natural light. While specific energy savings depend on existing lighting systems and usage patterns, the visual improvement also enhances safety and task performance, linking aesthetic choices to functional energy considerations.

How Does Epoxy Flooring Improve Safety in Garages and Basements?

Epoxy improves safety through slip-resistant additives, continuous seamless surfaces that reduce trip hazards, and light-reflective finishes that increase visibility in low-light areas. The ability to integrate textured aggregates or slip additives lets homeowners tailor traction characteristics to wet basements or oily garage floors. Continuous epoxy surfaces eliminate loose tiles or raised edges that create trips, while reflective systems make hazards easier to see. The following table outlines common slip-resistance additives, their texture level, and recommended residential use cases to help homeowners choose appropriate safety features.

Additive

Slip-Resistance Texture

Recommended Use Case

Vinyl or decorative flakes

Low–moderate texture

Garages, light-traffic basements where appearance matters

Quartz sand

Moderate texture

Driveway-facing garages and ramps with occasional moisture

Aluminum oxide

High texture and durability

Areas with heavy foot traffic or industrial workshop use

Anti-slip beads

Variable texture

Targeted traction zones like entryways or steps

What Slip-Resistant Additives Are Used in Epoxy Flooring?

Common slip-resistant additives include broadcast flakes, quartz sand, aluminum oxide, and proprietary anti-slip beads, each providing different texture levels and long-term durability. Flakes add visual camouflage and mild slip resistance, quartz increases grip for wetter conditions, and aluminum oxide offers a durable, high-traction surface for heavy-use areas. Additive choice depends on intended use, comfort underfoot, and maintenance tolerance because higher-texture surfaces may trap more dirt and require more frequent cleaning. Selecting the right additive aligns safety goals with aesthetic and maintenance preferences, which proceeds naturally to how visibility and markings further reduce hazards.

How Does Epoxy Flooring Increase Visibility and Reduce Trip Hazards?

Epoxy increases visibility by using lighter pigments or reflective flakes to boost light distribution, making low-light corners and steps easier to see and reducing the risk of trips. Continuous epoxy transitions prevent gaps or lifted edges that commonly create trip points between different flooring materials. Use of contrasting colors or textured borders can demarcate walkways, ramps, or work zones to guide movement safely. These combined strategies—improved reflectivity, seamless transitions, and deliberate color/texture markings—help homeowners create safer, more navigable spaces in garages and basements.

How Does Epoxy Flooring Act as a Moisture Barrier to Protect Your Home?

Epoxy acts as a moisture barrier by forming a continuous, non-porous membrane over concrete that blocks vapor and liquid migration through surface pores, reducing conditions that encourage mold, efflorescence, and floor deterioration. However, epoxy’s effectiveness depends on existing moisture levels and correct subfloor preparation; applying epoxy over excessive vapor emission can trap moisture and cause adhesion failures. Therefore, moisture testing and appropriate mitigation before installation are essential to ensure the coating functions as intended. Given these stakes, homeowners should consider professional inspection to assess vapor levels and subfloor readiness before committing to a coating system.

Why Is Epoxy Essential for Preventing Basement Mold and Mildew?

By sealing concrete pores and preventing surface moisture from lingering, epoxy reduces the damp microclimates where mold and mildew colonize on floors, thereby lowering one common source of microbial growth. That said, epoxy does not replace the need to address bulk water intrusion, poor drainage, or elevated sub-slab vapor pressure; those conditions require waterproofing or structural remedies before coating. For minor to moderate vapor issues, epoxy paired with a moisture-mitigation primer can effectively limit surface dampness and the associated microbial risk. Recognizing these limits clarifies when to pursue inspection and repair prior to coating.

How Does Proper Subfloor Preparation Enhance Epoxy’s Waterproofing?

Proper subfloor preparation—cleaning, crack repair, mechanical profiling (grinding or shot blasting), and moisture testing—creates the adhesive profile and dry conditions epoxy needs to bond and perform as a vapor barrier. Each prep step contributes: cleaning removes contaminants, crack filling stabilizes the surface, profiling exposes fresh concrete for mechanical keying, and moisture testing identifies vapor pressures that require mitigation. Without these steps, the coating risks blisters, delamination, or premature failure, which is why professional inspection and targeted repairs often precede a reliable epoxy installation.

What Related Services Should Homeowners Consider Alongside Epoxy Flooring?

Complementary services can determine the success and longevity of an epoxy installation: pre-installation free inspections, concrete repair (crack filling, leveling), and waterproofing or moisture mitigation when needed. These services identify hidden issues like elevated vapor emission, structural cracks, or surface contaminants that impair adhesion and long-term performance. Professional assessment reduces the likelihood of premature failure and ensures the chosen epoxy system matches site conditions and homeowner goals. Below is a practical checklist of what a free inspection typically covers, followed by a short explanation of repair options that commonly prepare concrete for epoxy coatings.

A typical free inspection helps homeowners understand readiness and next steps:

Moisture Testing: Measure slab vapor emissions to determine if mitigation is needed.

Visual and Structural Assessment: Identify cracks, spalling, and surface contamination.

Adhesion and Profile Check: Evaluate surface profile for adequate mechanical bonding.

Repair & System Recommendation: Provide tailored guidance on repairs and appropriate epoxy systems.

How Can Free Inspections Help Identify Waterproofing and Repair Needs?

Free inspections evaluate moisture emission rates, the condition of cracks and joints, and surface contamination that could block adhesion, delivering a repair and waterproofing plan tailored to the home’s slab conditions. Inspectors typically perform moisture testing, a visual crack and joint survey, and an assessment of surface profile to determine if grinding or shot blasting is necessary. The outcome is a clear recommendation that balances repair work, potential waterproofing, and the right epoxy system for the space. Homeowners benefit because the inspection reduces uncertainty and helps prevent costly installation failures due to overlooked conditions.

What Concrete Repair Solutions Complement Epoxy Floor Coatings?

Concrete repair options that support epoxy coatings include crack injection and filling, surface leveling, patching spalls, and use of moisture mitigation primers or vapor-reducing systems prior to coating. Crack repairs stabilize the slab and stop ongoing movement that would compromise rigid coatings; leveling creates a uniform plane for aesthetic finishes; and vapor primers or specialized membranes reduce sub-slab emissions where needed. Professional evaluation identifies which combination of repairs is appropriate, and coordinated repair plus coating work yields a longer-lasting, more reliable floor system.

(Note: To determine whether a repair or waterproofing step is needed for your space, scheduling a free inspection for waterproofing and repair assessments is a practical next step; inspections are no-obligation and clarify preparation requirements before installation.)

Protect your home or workspace with a floor that lasts. Schedule a free inspection with Midwest Floor Shield in Roscoe, Illinois, Madison, Wisconsin, or the surrounding areas to evaluate your concrete, identify moisture or repair needs, and receive expert guidance on the best epoxy or polyaspartic system for your garage, basement, or commercial space.

Act now to prevent costly flooring mistakes and enjoy a durable, safe, and visually stunning floor for years to come.