Polyaspartic Floor Coatings: Strength and Speed Combined

Written by Jonathan, owner of Midwest Floor Shield and dedicated content contributor. Jonathan doesn’t just write — he runs the business with a mission to help Midwest homeowners protect and transform their spaces with lasting floor coating solutions. His articles reflect both his hands-on experience and his commitment to guiding families in Beloit, WI, and beyond toward confident, worry-free decisions for their homes.

Why EpoxyFloors Fail and How Polyaspartic Coatings Provide Durable Solutions

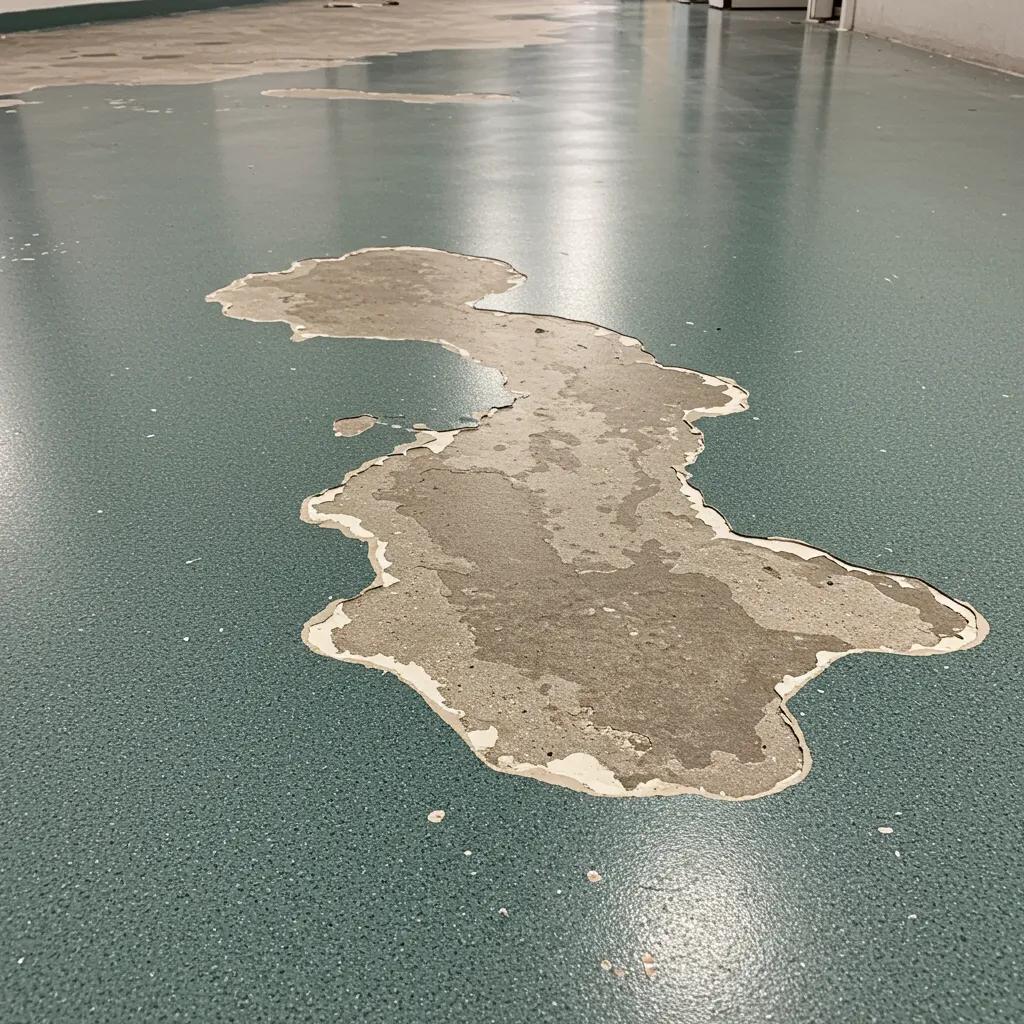

Epoxy floor coatings often peel, yellow, or delaminate within a few years, leaving concrete substrates exposed to stains and structural damage. Understanding why epoxyfloors fail—from inadequate surface preparation to moisture migration and UV degradation—reveals specific failure modes that compromise longevity. Polyaspartic coatings solve these problems by delivering superior adhesion, rapid cure times, UV stability, and chemical resistance for long-lasting garage floor protection and concrete defense. In this guide, we explore:

Main causes of epoxy peeling and delamination

How polyaspartic properties directly counter epoxy weaknesses

Key differences in durability, cost, and application

Surface preparation steps for both systems

Installation practices that reduce failures and maximize benefits

Common questions about epoxy failures and polyaspartic solutions

Environmental factors affecting performance

By mapping epoxy failure mechanisms to polyaspartic advantages, this article equips Midwest floor coating professionals and DIY enthusiasts with actionable strategies for durable floor protection in 10 2025 and beyond.

What Are the Main Causes of Epoxy Floor Peeling and Delamination?

Epoxy floor peeling and delamination stem from a combination of adhesion failures, moisture pressure, chemical incompatibility, UV damage, and thermal stresses. Each failure mode begins with an interaction between substrate conditions and resin chemistry—mapping these interactions guides effective prevention strategies and informs how polyaspartic coatings resolve them in subsequent sections.

How Does Poor Surface Preparation Lead to Epoxy Peeling?

Inadequate concrete profiling and cleaning prevents epoxyresin from forming a mechanical bond, so epoxy fails to anchor to the substrate. Surface contaminants such as oil, paint residues, or laitance create a non-porous barrier that causes weak adhesion. Diamond grinding or shot blasting should achieve a CSP 2–3 profile and remove all debris before primer application. Proper surface profiling supports epoxy bonding strength, setting the stage for moisture management techniques that follow.

Why Is Moisture a Critical Factor in Epoxy Floor Failure?

Moisture vapor pressure within concrete drives osmotic blistering, which forces epoxy layers to lift and delaminate. When hydrostatic pressure exceeds epoxy tensile strength, bubbles or blisters appear, eventually leading to full-scale peeling. Moisture testing using calcium chloride or relative humidity probes identifies vapor drive levels above 3 lbs/1,000 ft²/24 hr. Addressing moisture through vapor barriers or moisture-tolerant primers prevents pressure-induced delamination and transitions directly into chemical mixing considerations.

Inspection and Diagnosis of EpoxyResinIndustrial Floor CoatingsThe evolution of epoxyresin in industrial floor coatings (PIRE) over the past... engineers) as they can benefit from analyzing anomalies that may arise from inadequate...Inspection and diagnosis of epoxyresinindustrial floor coatings, J Garcia, 2008

How Do Improper Mixing and Curing Affect EpoxyDurability?

Incorrect resin-to-hardener ratios disrupt the polymerization reaction, leaving unreacted monomers and reducing cross-link density. This chemical incompatibility yields soft spots, tacky surfaces, and poor abrasion resistance. Temperature-controlled mixing and strictly following manufacturer-specified pot life ensure complete cure. Uniform mixing promotes consistent mechanical properties, paving the way for understanding UV stability challenges in epoxysystems.

What Role Does UV Exposure Play in Epoxy Yellowing and Degradation?

Ultraviolet radiation breaks down polymer chains in epoxy formulations, causing yellowing, chalking, and surface cracking. UV light initiates photo-oxidation that weakens molecular bonds, resulting in loss of gloss and surface integrity. Epoxy UV degradation accelerates aesthetic decline and invites further moisture infiltration. Recognizing UV as a primary degradation catalyst leads to examining hot tire pickup and chemical resistance limits next.

Polycarbamide Coatings: UV Stability and Epoxy Floor ProtectionFurthermore, polycarbamide coatings exhibit excellent UV and light stability and are applied to the floor to provide enhanced protection to the underlying decorative elements of the epoxyflooringsystem.Floor Coatings, Unknown Author, Unknown

How Do Hot Tire Pickup and Chemical Stains Cause Epoxy Damage?

Heat from vehicle tires can soften epoxy surfaces, allowing tires to adhere and pull off coatings—known as hot tire pickup. Strong solvents, oil, gasoline, and acidic cleaners attack epoxy’s chemical matrix, causing stains and etching. Epoxy’s limited thermal and chemical resistance leads to stress fractures and discoloration. These vulnerabilities illustrate why a more durable coating technology is essential for demanding garage and industrial environments.

Case Study of a Defective EpoxyResinFlooring SystemEpoxy resins are synthesized from prepolymers that contain, on average, two or more epoxy groups per molecule. When these components...When polymers fail: A case report on a defective epoxyresinflooring, Unknown Author, 2007

How Do Polyaspartic Coatings Overcome Epoxy Floor Problems?

Polyaspartic coatings leverage fast-reacting esters and polyurea crosslinkers to deliver robust adhesion, UV stability, chemical resistance, and abrasion tolerance. By combining rapid cure chemistry with moisture-insensitive formulations, polyasparticsystems form a continuous, flexible film that bonds tightly to prepared concrete. The seamless integration of polyaspartic properties directly addresses each epoxy failure mechanism, ensuring long-term protection under heavy traffic and environmental stressors.

What Makes Polyaspartic Coatings More Durable Against Abrasion and Impact?

Polyaspartic crosslinks create a highly elastic network that dissipates mechanical stress, resisting scuffs, scratches, and impact from dropped tools. Laboratory abrasion tests show polyasparticsystems sustaining over 200 mg wear per 1,000 cycles versus 500 mg for standard epoxy. Enhanced toughness minimizes chipping and surface erosion, making polyaspartic ideal for high-traffic garages and commercial floors. Superior abrasion resistance naturally leads to examining the benefits of rapid cure times.

How Does Polyaspartic’s Fast Cure Time Benefit Installation and Use?

Polyaspartic coatings cure to foot traffic in 2–4 hours and full chemical resistance in 24 hours, compared to 24–72 hours for epoxy. Rapid curing reduces downtime by over 80 percent, enabling same-day return to service for residential garages and retail spaces. Fast cure kinetics also limit dust contamination and environmental exposure during installation. Quick turnaround underscores the advantage of UV stability, which we explore next.

Why Is Polyaspartic More Resistant to UV Damage and Yellowing?

Polyaspartic formulations incorporate UV-stable aliphatic backbones that absorb minimal ultraviolet radiation and resist photo-oxidation. This stability prevents chalking and maintains gloss levels over time, preserving color integrity in sunlit garages and exterior applications. UV resistance extends aesthetic lifespan by up to 10 years, eliminating the yellowing typically seen in epoxyfloors. Sustained UV stability reinforces the coating’s chemical defense capabilities.

How Do Polyaspartic Coatings Resist Chemicals and Stains Better Than Epoxy?

Polyaspartic films exhibit high crosslink density that repels oil, gasoline, battery acid, and cleaning solvents without etching or discoloration. Chemical resistance ratings exceed ASTM D543 standards, showing negligible mass loss after 28 days of acid or alkali immersion. This resilience prevents staining and surface deterioration even under harsh automotive or industrial spills. Robust chemical resistance naturally complements moisture mitigation strategies detailed below.

In What Ways Does Polyaspartic Provide Better Adhesion and Moisture Mitigation?

Moisture-tolerant polyaspartic primers bond to concrete with a tensile adhesion strength exceeding 600 psi, outperforming epoxy’s 400 psi average. Hydrostatic moisture barriers integrated into the primer block vapor drive up to 18 lbs/1,000 ft²/24 hr. This dual action—strong adhesion combined with moisture barrier properties—prevents blistering and delamination. Superior moisture mitigation ensures long-term integrity and transitions to a direct comparison between epoxy and polyaspartic.

What Are the Key Differences Between Epoxy and Polyaspartic Floor Coatings?

Definition + Mechanism + Benefit: Epoxy coatings use bisphenol-A resinsystems that cure slowly and resist abrasion moderately, while polyaspartic coatings employ fast‐curing aliphatic polyurea esters that deliver superior durability, UV stability, and chemical resistance. Contractors and homeowners choose between cost, performance, and downtime to match project requirements.

This comparison reveals polyaspartic’s clear performance advantages in critical attributes.

How Do Epoxy and Polyaspartic Compare in Lifespan and Durability?

Epoxy coatings typically last 5–7 years under residential use before chipping, peeling, or yellowing appear. Polyasparticsystems deliver 15–25 years of service, resisting wear, UV exposure, and chemical attack. The higher crosslink density and moisture barrier properties in polyaspartic formulations drive this lifespan extension, reducing recoat frequency and lifecycle costs.

What Are the Cost Implications of Choosing Epoxy vs. Polyaspartic?

While initial material and labor costs for polyaspartic can be 20–30 percent higher than epoxy, total cost of ownership favors polyaspartic over time. Fewer recoats, reduced downtime, and minimal maintenance translate into lower lifecycle expenses. A 10-year cost comparison shows polyaspartic projects requiring one recoat versus two for epoxy, saving up to 25 percent in long-term expenditures.

Which Floor Coating Is Best for Different Environments and Uses?

Epoxy suits low-traffic basements or decorative interior spaces where UV exposure and chemicals are minimal. Polyaspartic excels in heated garages, showrooms, food processing areas, and outdoor patios exposed to sunlight, moisture, and heavy wear. Selecting the optimal coating depends on traffic intensity, environmental stresses, and desired maintenance intervals.

How Does Surface Preparation Impact the Success of Epoxy and PolyasparticFloors?

Surface preparation defines coating performance by creating clean, profiled substrates for resin bonding. Proper concrete prep involves profiling, contaminant removal, and moisture assessment to prevent adhesion failures across both epoxy and polyasparticsystems.

What Are Best Practices for Preparing Concrete Before Epoxy Application?

Concrete profiling with diamond grinders or shot blasting achieves a CSP 2–3 profile, creating anchor points for epoxy. Oil and grease stains must be removed with alkaline cleaners, and cracks repaired with cementitious patching compounds. A clean, dry substrate under 3 lbs/1,000 ft²/24 hr moisture drive is mandatory. These steps establish adhesion points that reduce peeling and blistering.

How Is Surface Preparation Different for Polyaspartic Coatings?

Polyaspartic primers require similar profiling but can tolerate higher moisture levels and colder temperatures during installation. Shot blasting to CSP 2–3 remains essential, but moisture-barrier primers permit up to 18 lbs/1,000 ft²/24 hr vapor drive. This flexibility allows installations in damp environments where epoxy would fail, highlighting polyaspartic’s superior moisture mitigation.

How Does Moisture Testing Prevent Coating Failures?

Moisture testing using relative humidity probes or calcium chloride tests identifies vapor drive levels that exceed coating tolerances. Mapping slab moisture at multiple points ensures accurate risk assessment. By confirming moisture conditions before coating, installers choose appropriate primers and barrier systems to prevent hydrostatic blistering and ensure long-term adhesion.

What Installation Practices Reduce Epoxy Floor Failures and Maximize Polyaspartic Benefits?

Proper installation practices—from environmental controls to professional workmanship—determine coating longevity. Understanding common DIY pitfalls and professional techniques ensures optimal results for both epoxy and polyaspartic floorsystems.

Why Do DIY Epoxy Installations Often Lead to Failure?

DIY epoxy projects frequently fail due to inadequate surface profiling, incorrect mixing ratios, and uncontrolled environmental conditions. Homeowners may overlook moisture testing and temperature guidelines, resulting in poor adhesion and extended curing times. These mistakes highlight the importance of professional approaches when durability is critical.

How Does Professional Installation Improve Polyaspartic Floor Performance?

Trained installers use precision mixing equipment, climate-controlled environments, and moisture-barrier primers to achieve consistent film thickness and adhesion. Professional application techniques—such as multi-coat roller systems and broadcast flake distribution—ensure seamless coverage and structural integrity. Expert workmanship fully realizes polyaspartic’s rapid cure and performance advantages.

What Are the Recommended Conditions and Techniques for Polyaspartic Application?

Polyaspartic coatings require substrate temperatures between 50–90 °F and humidity below 85 percent for optimal cure. Applying primers at 6–8 mils, base coats at 10–12 mils, and topcoats at 3–5 mils ensures balanced flexibility and hardness. Controlled ventilation removes off-gassing and supports rapid polymer crosslinking, delivering a durable, glossy finish.

What Are Common Questions About Epoxy Failures and Polyaspartic Solutions?

Reviewing frequent concerns clarifies decision-making and establishes confidence in coating selection and application strategies.

Why Do EpoxyFloors Peel Off Concrete Surfaces?

Epoxyfloors peel when surface contaminants, moisture pressure, or improper mixing create weak adhesion zones. Without mechanical keying and moisture barriers, resin layers cannot withstand substrate forces, leading to delamination.

Is Polyaspartic Coating Better Than Epoxy for GarageFloors?

Yes, polyaspartic coatings outperform epoxy in UV stability, abrasion resistance, chemical defense, and rapid cure time, making them the superior choice for garage environments with heavy traffic and exposure.

Can Polyaspartic Be Applied Over Existing EpoxyFloors?

Yes, polyaspartic coatings bond well to fully cured and properly prepared epoxy surfaces. Diamond grinding the old epoxy layer and using a compatible primer ensure strong adhesion and seamless integration.

How Long Do PolyasparticFloors Typically Last Compared to Epoxy?

Polyasparticfloors last 15–25 years under normal use, compared to 5–7 years for epoxysystems. Extended lifespan results from superior crosslink density, UV stability, and moisture barrier performance.

What Maintenance Is Required for Polyaspartic vs. EpoxyFloors?

Both coatings benefit from regular cleaning with pH-neutral detergents. Polyasparticfloors require less frequent recoating and resist stains more effectively, while epoxyfloors often need touch-ups and scuff repair within 2–3 years.

How Do Environmental Factors Affect Epoxy and Polyaspartic Floor Performance?

Climate and external conditions influence coatingdurability by altering substratemoisture, thermal expansion, and UV exposure. Matching coating chemistry to environmental stressors ensures optimal performance in any region.

How Does Humidity and Moisture Variation Influence Epoxy Floor Failures?

High humidity and slab moisture drive accelerate epoxy blistering and delamination by increasing hydrostatic pressure. Seasonal moisture fluctuations can lift epoxy films if vapor barriers are absent, underscoring the need for moisture-tolerant primers.

Why Is Polyaspartic More Suitable for Extreme Temperature Fluctuations?

Aliphatic polyaspartic networks flex with concrete’s thermal expansion and contraction, resisting cracking in freeze-thaw cycles. Broad service temperature ranges (–40 °F to 180 °F) ensure stable performance in hot summers and cold winters.

What Is the Impact of UV Exposure on Outdoor Floor Coatings?

Outdoor UV exposure degrades standard epoxy through photochemical chain scission, causing yellowing and chalking. Polyaspartic coatings resist UV-induced damage, retaining gloss and color for years under direct sunlight.

Epoxy coatings frequently fail due to poor preparation, moisture pressure, improper curing, UV degradation, and chemical attack. Polyasparticsystems overcome these challenges with fast cure, strong adhesion, UV stability, and chemical resistance—extending floor lifespan and reducing maintenance. By following best practices in surface profiling, moisture testing, and application conditions, stakeholders achieve durable, attractive floors that protect concrete and deliver long-term value. Confidence in coating selection grows from matching environmental demands to the right resin technology and relying on professional installation standards.